- Tapes by Type

-

Tapes by Application

- About

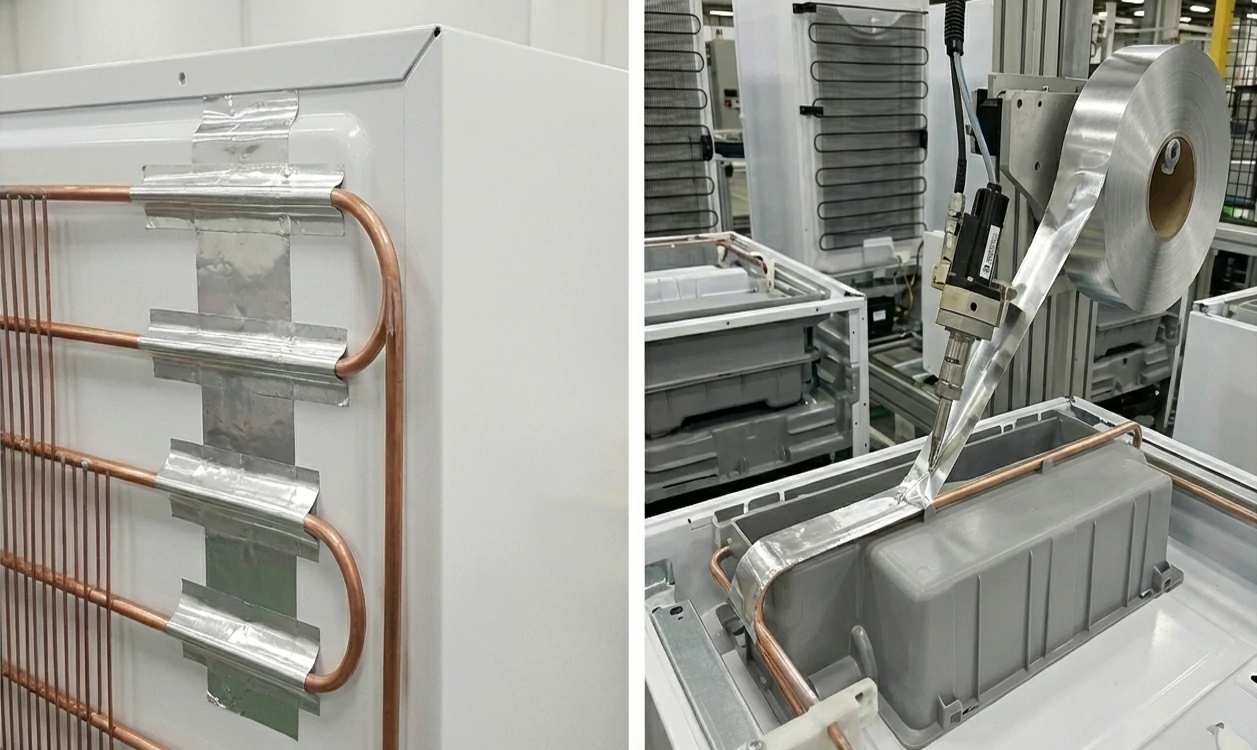

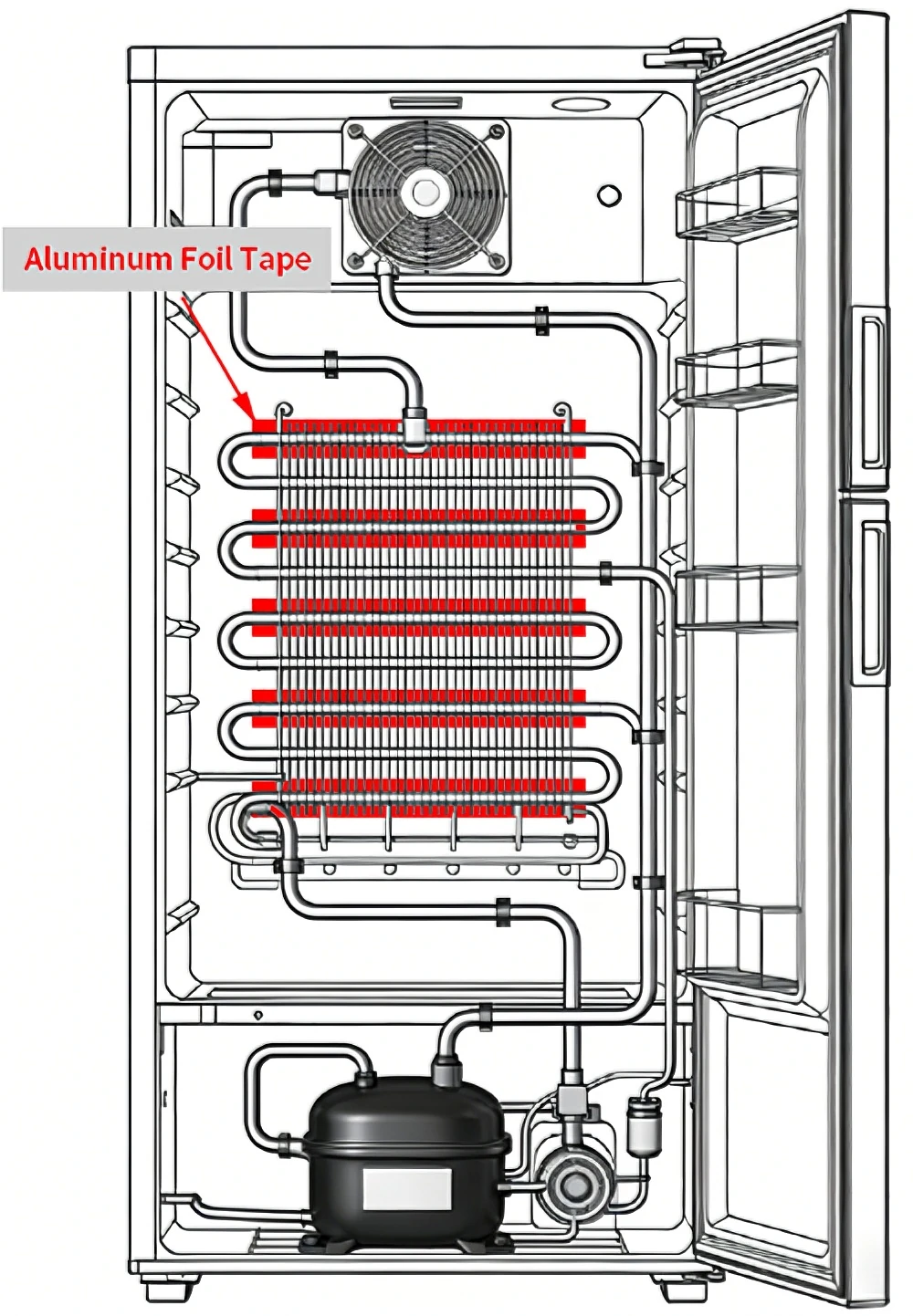

Aluminum Polyester Tape is a high-performance industrial adhesive solution developed for demanding refrigeration and white goods applications. By combining aluminum foil with PET film, this advanced laminate tape delivers superior tensile strength, tear resistance, and thermal performance compared to traditional aluminum foil tape. The aluminum foil polyester tape is widely used for fastening condenser tubes and evaporator coils in refrigerators and freezers, supporting efficient heat transfer and reliable long-term bonding in automated production environments.

Unlike standard aluminum foil tape, this specialized laminate offers a sophisticated multi-layer construction designed for durability and ease of use:

A high-strength polyester-aluminum laminate backing. The inclusion of PET film provides significantly higher tensile strength and tear resistance compared to pure aluminum foil.

The outer PET film is coated with a silicone-based release system. This allows the tape to be self-wound without a traditional release liner, streamlining automated production and reducing waste.

Coated with a high-performance, solvent-based acrylic adhesive. This ensures a strong, reliable bond with excellent initial tack to both metals and common industrial plastics.

Aluminum Polyester Tape is the industry standard for the automated manufacturing of refrigerators and freezers. Its primary roles include:

This tape is designed to attach condenser tubes or coils directly to the appliance housing. By creating a tight, gap-free bond, it maximizes thermal transfer efficiency, helping appliances maintain optimal cooling while reducing energy consumption.

Commonly used as a refrigerator aluminum tape, it facilitates the bonding of metallic cooling tubes to plastic housings. This is critical for maintaining the structural integrity and long-term durability of the cooling system.

The pressure-sensitive adhesive ensures a tight bond that optimizes heat exchange, directly contributing to the energy star rating of cooling appliances.

By laminating aluminum with polyester, this tape provides far better resistance to snapping or stretching than traditional foil tapes, ensuring a permanent hold on heat-exchanging tubes.

Available in massive 400-meter rolls, this tape is perfectly compatible with continuous automated application lines, ensuring consistent pressure and high production speeds.

Despite the polyester layer, the aluminum core facilitates efficient heat transfer across the bonded surface.

PET layer improves dispensing performance, reducing production delays and ensuring hassle-free application.

Adapts to surfaces for a tight, secure bond between cooling tubes and refrigerator housings.

Immediate bonding to plastics and metals minimizes rework and ensures the cooling coils stay in place during the foaming or assembly process.

When it comes to the "White Goods" industry, precision and efficiency are everything. Aluminum Polyester Tape provides a robust, automation-ready solution that exceeds the capabilities of standard aluminum foil tape. By offering superior strength and excellent thermal properties, it ensures that refrigerators and freezers operate at peak performance for years to come.