In modern HVAC systems, maintaining sealing integrity is a critical component of overall efficiency. Air Duct Aluminum Foil Tape serves as one of the most effective solutions for managing joints, seams, and insulation within these systems. Whether you are a building manager, a professional HVAC contractor, or a proactive homeowner, understanding the correct use of aluminum foil tape for ductwork is essential to prevent air leakage, energy loss, and costly system inefficiencies.

What Is Air Duct Aluminum Foil Tape?

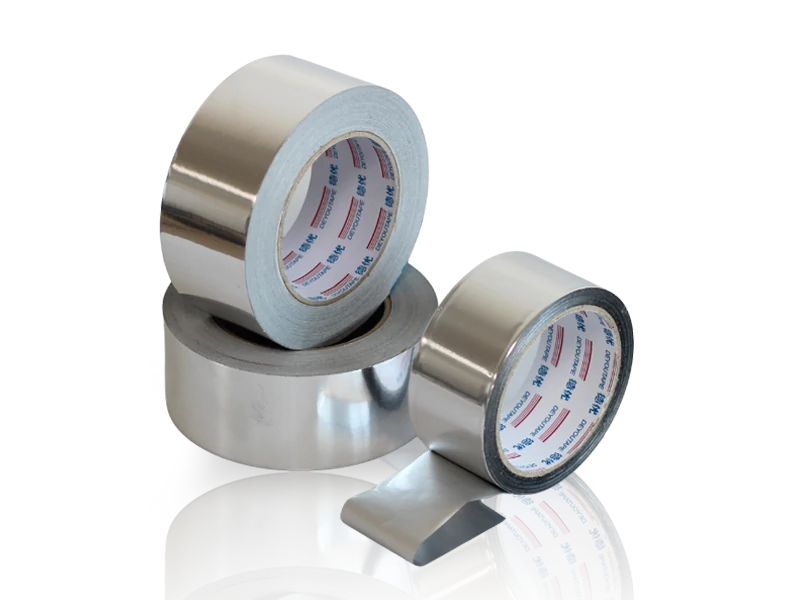

Air duct aluminum foil tape is a specialized pressure-sensitive tape. It consists of an aluminum foil backing coated with a high-performance adhesive, typically solvent-based or acrylic. It is designed for:

- HVAC duct sealing

- Insulation joint bonding

- Vapor barrier reinforcement

- Air leakage prevention

Unlike traditional cloth-based AC duct tape, aluminum foil tape for ductwork resists heat, humidity, and aging. It provides a permanent metal-to-metal bond suitable for demanding HVAC environments.

Why Standard AC Duct Tape Fails

Conventional cloth duct tape was never designed for long-term HVAC sealing. Air ducts operate under demanding conditions, including high air pressure and constant temperature cycling. Under real operating conditions, it tends to:

- Dry out and crack

- Lose adhesion during temperature cycling

- Fail in humid or condensation-prone areas

This results in foil tape adhesive failure comparisons that clearly favor aluminum solutions. In contrast, insulation duct tape made with foil backing maintains adhesion integrity and vapor sealing performance.

Key Advantages of Aluminum Foil Tape for Ductwork

1. Superior Adhesion Strength

High-quality aluminum tape for ductwork uses aggressive acrylic adhesive that bonds securely to:

- Galvanized steel ducts

- Aluminum duct systems

- Flexible duct connectors

- Insulation jackets

This reduces seam separation and long-term maintenance issues.

2. High Temperature Resistance

HVAC systems operate under constant thermal cycling. Foil tape for ductwork withstands:

- Low temperatures in cooling systems

- Elevated temperatures in heating systems

The adhesive remains stable without brittleness or delamination.

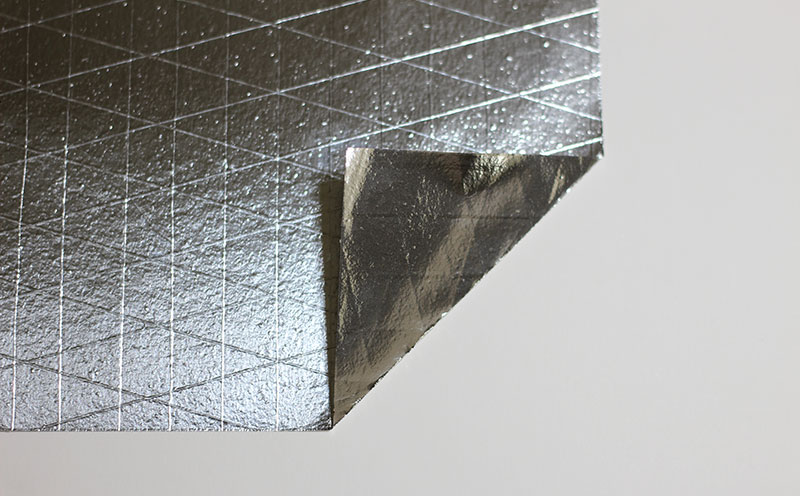

3. Vapor & Moisture Barrier Protection

Condensation is one of the leading causes of insulation damage. Aluminum foil backing functions as a moisture barrier, making it ideal as insulation duct tape for vapor sealing applications.

4. Reflective Surface for Thermal Efficiency

The aluminum layer reflects radiant heat, contributing to improved system efficiency and reduced thermal loss.

Common Applications

Air Duct Aluminum Foil Tape is widely used in:

- Residential HVAC systems

- Commercial ventilation systems

- Industrial air handling units

- Insulated duct wrap sealing

- Refrigeration duct systems

- Cleanroom HVAC installations

It is particularly effective where aluminum foil tape for ductwork must maintain both air sealing and vapor integrity.

How to Choose the Right Aluminum Tape for Ductwork

For commercial or contractor-grade performance, evaluate these technical factors:

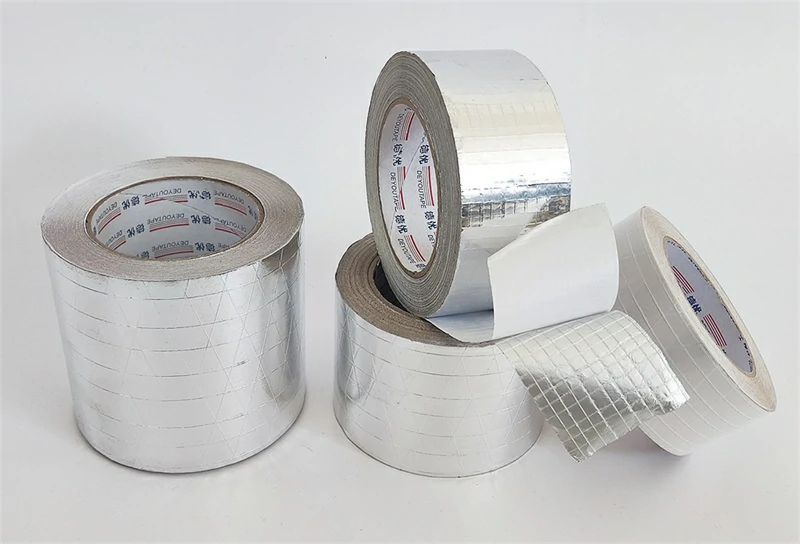

Foil Thickness

Thicker foil provides:

- Greater tear resistance

- Improved durability

- Enhanced dimensional stability

Adhesive Technology

- Acrylic adhesive: Excellent aging resistance and long-term stability

- Solvent-based adhesive: Stronger initial tack in colder conditions

Temperature Rating

Ensure compatibility with both heating and cooling cycles.

Certification Requirements

Projects may require UL-listed or code-compliant foil tape for ductwork installations.

Proper Installation: Maximizing Performance

Even premium insulation duct tape can fail if applied incorrectly. Follow these best practices:

- Clean surfaces thoroughly (remove dust, oil, and moisture).

- Apply within recommended temperature range.

- Use firm pressure with a squeegee to activate the pressure-sensitive adhesive.

- Avoid stretching during application.

- Overlap seams by at least ½ inch for airtight sealing.

Correct installation significantly reduces the risk of foil tape adhesive failure.

Aluminum Foil Tape vs. Other Sealing Methods

| Feature | Aluminum Foil Tape | AC Duct Tape | Mastic Sealant |

|---|---|---|---|

| Heat Resistance | High | Low | High |

| Moisture Barrier | Yes | Limited | Yes |

| Clean Application | Yes | Yes | No |

| Cure Time | Instant | Instant | Requires Drying |

| Longevity | Long-Term | Short-Term | Long-Term |

For fast, clean, and durable results, aluminum foil tape for ductwork remains the preferred choice.

Commercial Benefits for Contractors & Distributors

Using professional-grade Air Duct Aluminum Foil Tape delivers measurable value:

- Reduced energy loss

- Improved HVAC efficiency

- Lower operational costs

- Enhanced indoor air quality

- Extended equipment lifespan

- Fewer callbacks and repairs

For contractors, specifying high-quality foil tape for ductwork builds long-term client trust and project credibility.

Conclusion

Air Duct Aluminum Foil Tape is a critical component in HVAC system performance. Compared to traditional AC duct tape, it provides superior adhesion, thermal resistance, and vapor protection.

For informational buyers evaluating performance—and commercial purchasers seeking reliable supply—choosing the right aluminum tape for ductwork directly impacts efficiency, durability, and code compliance.

Secure Your System with Deyou Tape

At Deyou Tape, we provide professional-grade adhesive solutions designed to meet the most rigorous industrial standards. Our Air Duct Aluminum Foil Tape ensures your HVAC system remains sealed, efficient, and reliable through every season.