In construction, HVAC, and industrial maintenance, low temperatures are one of the biggest challenges to achieving a reliable seal. Many standard tapes lose adhesion, become brittle, or fail completely when applied in cold environments. To ensure a permanent, airtight bond in freezing environments, professionals rely on Cold Weather Aluminum Foil Tape.

Engineered specifically for low-temperature conditions, cold weather foil tape delivers dependable adhesion where standard aluminum foil tape and general cold weather tape cannot. This guide explains how it works, why it matters, and how to choose the right solution for cold-climate applications.

What Is Cold Weather Aluminum Foil Tape?

Cold Weather Aluminum Foil Tape is a specialized form of aluminum foil tape formulated with a cold-resistant adhesive that remains flexible and tacky at low temperatures. Unlike conventional foil tapes designed for moderate conditions, this Cold Weather Aluminum Tape maintains strong bonding performance during both application and long-term service in cold environments.

It combines:

- A durable aluminum foil backing for strength, vapor resistance, and moisture protection.

- A specially engineered cold weather adhesive that performs reliably in near-freezing and sub-zero temperatures.

As a result, Cold Weather Foil Tape is widely used for sealing, insulation, and moisture control in winter or cold-climate installations.

Why Standard Aluminum Foil Tape Fails in Cold Conditions

Most standard aluminum foil tape is optimized for room-temperature application. When used in the cold, they encounter three primary hurdles:

- Adhesive Hardening: The adhesive loses its "flow," becoming a hard, non-tacky solid that cannot penetrate the surface of the duct or insulation.

- Failure to "Wet Out": Proper adhesion requires the glue to spread across the surface (wetting out). In the cold, this process stops, preventing a secure bond.

- Surface Frost: Cold surfaces often harbor microscopic layers of frost. Without a specialized cold weather adhesive tape, the tape will simply slide off or peel away within hours.

These issues often lead to peeling, edge lifting, and air or moisture leakage. Cold weather adhesive tape overcomes these problems by maintaining flexibility and surface contact even in freezing conditions.

The Technology Behind Cold Weather Foil Tape

The performance of cold weather premium foil tape depends largely on its adhesive chemistry.

Specialized Acrylic Adhesives

High-performance cold weather foil tapes typically use advanced acrylic adhesives rather than rubber-based systems.

Key advantages include:

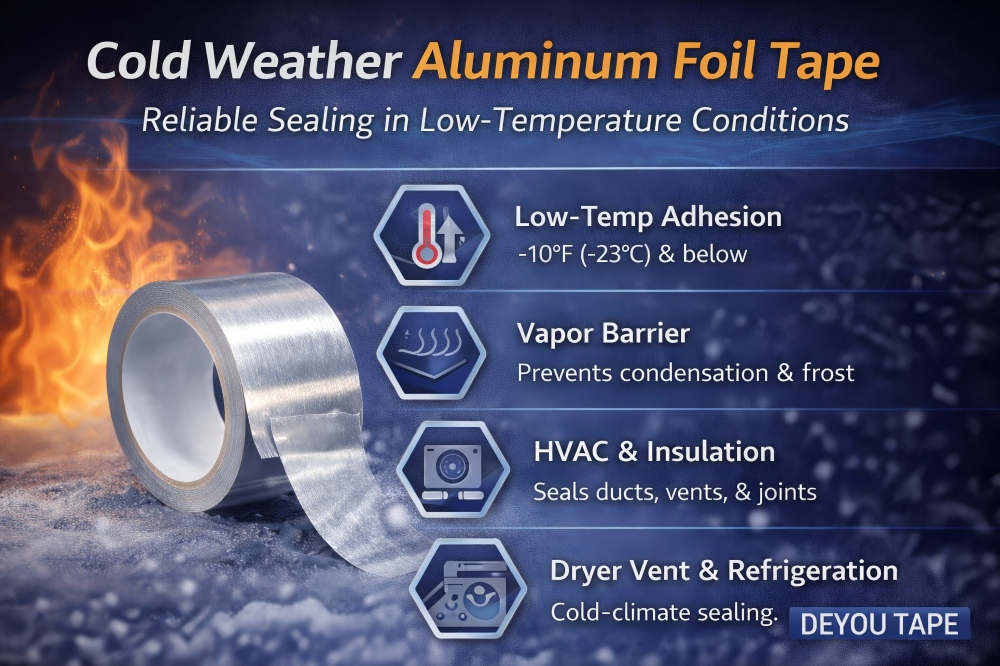

- Sub-zero application capability: Can be applied at temperatures as low as –10°F (–23°C).

- Wide operating range: Commonly rated from –30°C to 150°C (–22°F to 302°F).

- Long-term durability: Excellent resistance to UV exposure, moisture, and aging.

Paired with aluminum foil backing, these adhesives ensure strong, lasting seals in harsh winter environments.

Key Performance Characteristics

When evaluating Cold Weather Aluminum Foil Tape, consider these benchmarks:

- Low-temperature adhesion: Reliable bonding during winter installation.

- Vapor and moisture barrier: Prevents condensation and frost buildup.

- Mechanical durability: Foil backing resists tearing and deformation.

- Thermal stability: Performs across wide temperature fluctuations.

These properties are critical in applications such as HVAC systems and insulation projects.

Common Applications for Cold Weather Aluminum Foil Tape

Cold weather foil tape is essential in industries where temperature control is challenging:

HVAC and Duct Sealing

Used for sealing seams and joints in air handling systems. This includes specialized uses like cold weather foil tape for dryer vent installations, where the tape must handle the contrast between cold exterior walls and hot exhaust air.

Insulation Projects

Joining insulation panels to create continuous vapor barriers in cold climates.

Refrigeration & Cold Storage

Sealing panels and joints in walk-in freezers and cold rooms where standard tape fails.

Industrial & Outdoor Use

Protecting cables, pipes, and equipment in unheated or outdoor environments.

How to Choose the Right Cold Weather Foil Tape

When selecting a Cold Weather Aluminum Foil Tape, evaluate the following:

- Minimum Application Temperature: Check the manufacturer's specs. Ensure the tape is rated for the temperature at the moment of application.

- Adhesive Type: Look for solvent-based acrylic adhesives, which are superior to rubber-based adhesives in cold climates.

- Foil Thickness: A thicker foil (measured in mils) provides better puncture resistance and a more robust vapor barrier.

- Surface Preparation: Even with the best tape, surfaces should be wiped clean of visible ice, moisture, or oil for the strongest bond.

Choosing the right product ensures reliable performance and reduces costly rework.

Conclusion

Cold Weather Aluminum Foil Tape is a critical solution for sealing and insulation in low-temperature environments. By combining a robust aluminum foil backing with a cold-resistant adhesive, it delivers dependable performance where standard aluminum foil tape and general cold weather tape fall short.

For HVAC systems, insulation, dryer vents, and refrigeration applications, cold weather premium foil tape ensures strong adhesion, moisture protection, and long-term durability—even in sub-zero conditions.

Looking for reliable Cold Weather Aluminum Foil Tape?

At Deyou Tape, we specialize in high-performance adhesive solutions designed for the most challenging environments. From extreme heat to sub-zero cold, our professional-grade tapes provide the technical authority and durability your projects demand.

Contact Deyou Tape today to find the perfect tape for your next cold-weather project.