Aluminum foil tape for HVAC systems is an indispensable material used for sealing, insulating, and ensuring optimal performance across various HVAC components. Whether you are working with ductwork, air handlers, or refrigerant lines, using high-quality HVAC aluminum tape ensures efficiency and durability. This guide will explain the essential areas in an HVAC system where aluminum foil tape is crucial and why it’s the preferred choice.

Why Choose Aluminum Foil Tape for HVAC?

HVAC systems rely on sealed ducts to efficiently distribute conditioned air throughout a building. Even small gaps or unsealed joints in ductwork can lead to significant energy loss, reduced system performance, and increased utility costs.

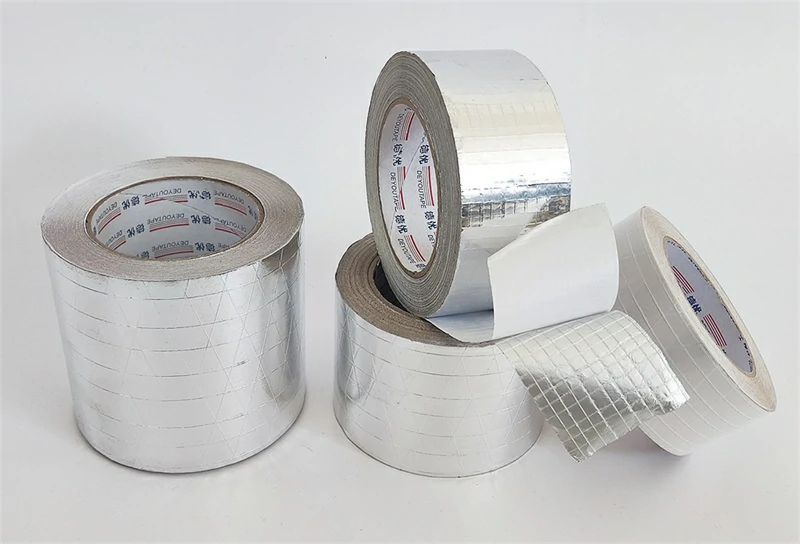

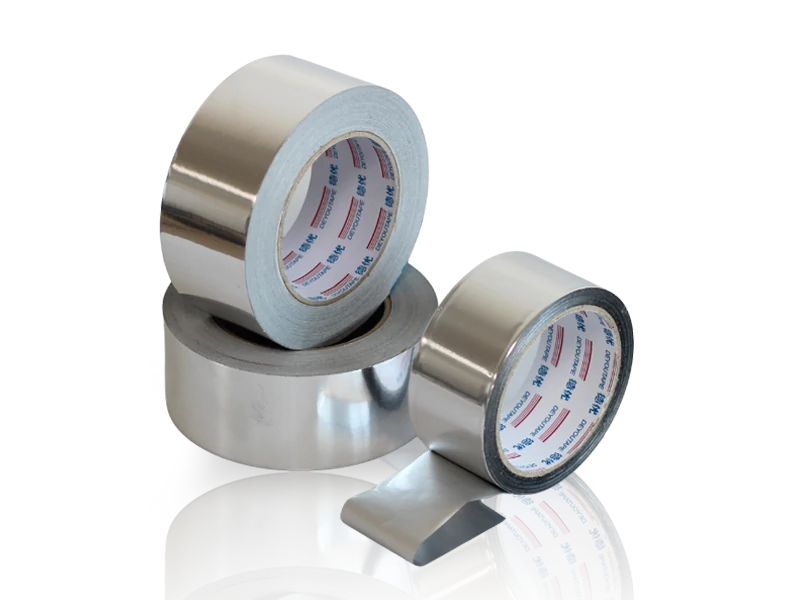

Aluminum foil tape is specifically designed to handle the demands of HVAC systems. These tapes provides an airtight and moisture-resistant seal, addressing these issues effectively. It is durable, weather-resistant, and able to withstand temperature fluctuations, making it perfect for sealing and insulating critical components. Its strong adhesive ensures a lasting bond, even in high-pressure or high-temperature environments.

When selecting HVAC tape, it is important to choose a product that is specifically rated for HVAC use. Not all aluminum foil tapes are created equal, and using a non-HVAC-grade tape may result in poor performance and premature failure.

Key Applications of Aluminum Foil Tape in HVAC Systems

1. Sealing Ductwork and Ducts

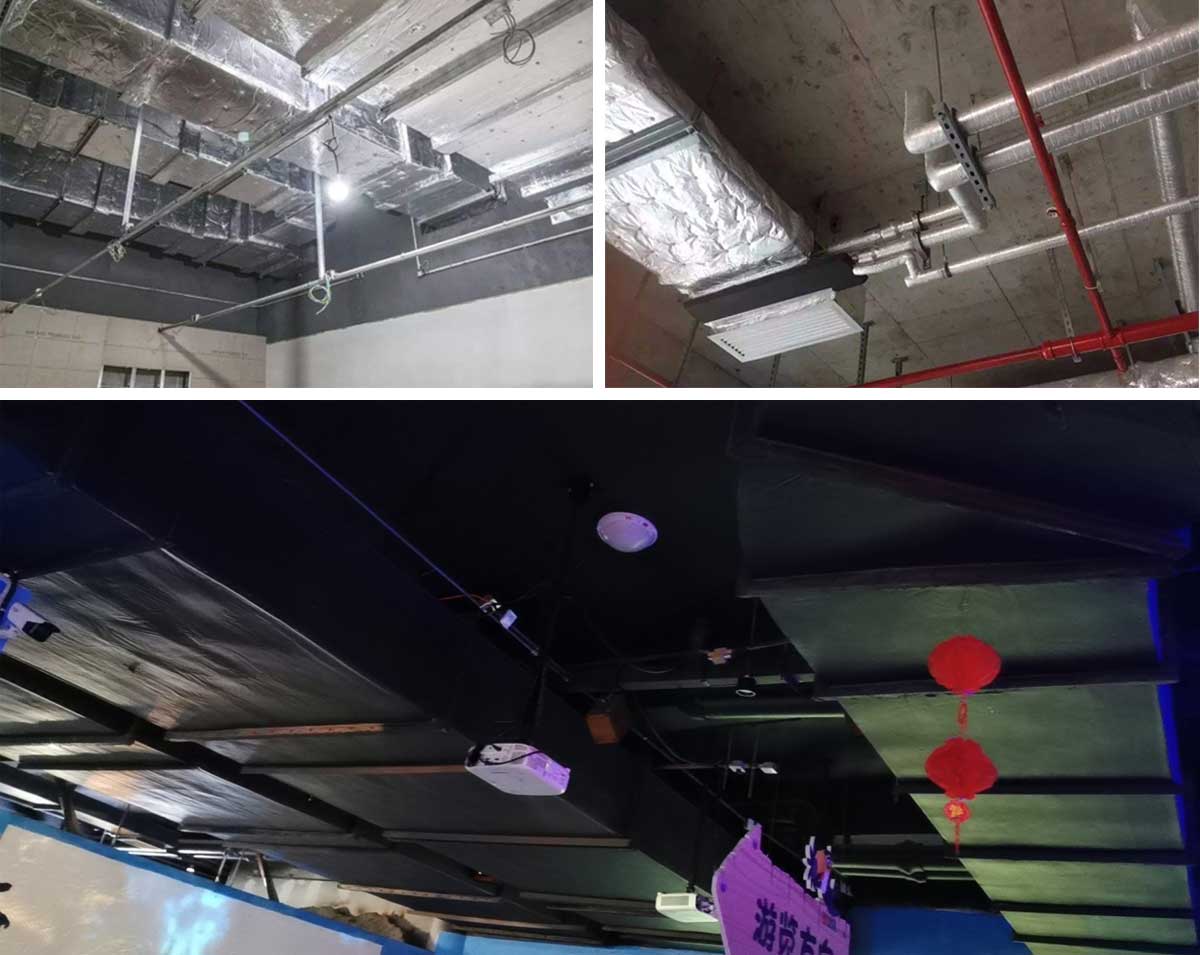

One of the primary uses of aluminum foil tape in HVAC systems is for sealing joints in ductwork and air ducts. Whether you're working with rigid or flexible duct systems, aluminum foil tape creates a strong, durable seal that prevents air leakage, which can lead to energy loss. Aluminum foil tape is particularly effective in flexible ducts, where it conforms to the irregular shapes and curves of the ducts. A tight seal in the ducts ensures that conditioned air reaches its destination without loss, maintaining system efficiency.

2. Insulating Ductwork and Pipes

Another essential use of HVAC aluminum tape is for securing insulation materials around ducts and refrigerant pipes. Proper insulation helps to prevent heat loss or gain as air travels through the ducts. Aluminum foil tape holds insulation in place, ensuring that there are no gaps that could compromise system efficiency. This use is vital for maintaining energy savings and enhancing the overall performance of the HVAC system.

3. Air Handler Seals

Inside the air handler unit, aluminum foil tape plays a significant role in sealing connections between components such as the blower, filter housing, and coil. Properly sealed connections ensure that airflow is directed along the correct path, and prevent air from leaking out of the system. This contributes to more efficient cooling and heating cycles, ensuring the system works at its full capacity.

4. Insulating Refrigerant Lines

HVAC aluminum tape is also commonly used for wrapping refrigerant lines. The tape provides a protective layer that helps prevent condensation from forming on the outside of refrigerant lines. This is crucial because condensation can lead to corrosion and other potential issues. Insulating refrigerant lines with aluminum foil tape helps to maintain the system's efficiency and prolong its lifespan.

Conclusion

In summary, aluminum foil tape for HVAC is an essential component in maintaining system efficiency and longevity. From sealing ductwork to insulating pipes and refrigerant lines, this versatile tape is indispensable in ensuring that your HVAC system operates smoothly. Whether you're a professional or a DIY enthusiast, using the right HVAC tape for sealing and insulating will help you avoid costly repairs and ensure long-term performance.

For more information or to purchase high-quality aluminum foil tape for your HVAC system, consult a trusted HVAC supplier Deyou Tape.