Air leaks in HVAC ductwork are a major cause of energy loss, uneven temperatures, and reduced system efficiency. Using HVAC duct sealing tape, specifically aluminum foil tape for air ducts, is one of the most effective and widely recommended methods for sealing leaks in both residential and commercial HVAC systems.

This step-by-step duct sealing guide explains how to seal HVAC ducts properly using aluminum foil tape, outlines best practices, and helps you choose the best tape for sealing air ducts.

Why Use HVAC Duct Sealing Tape?

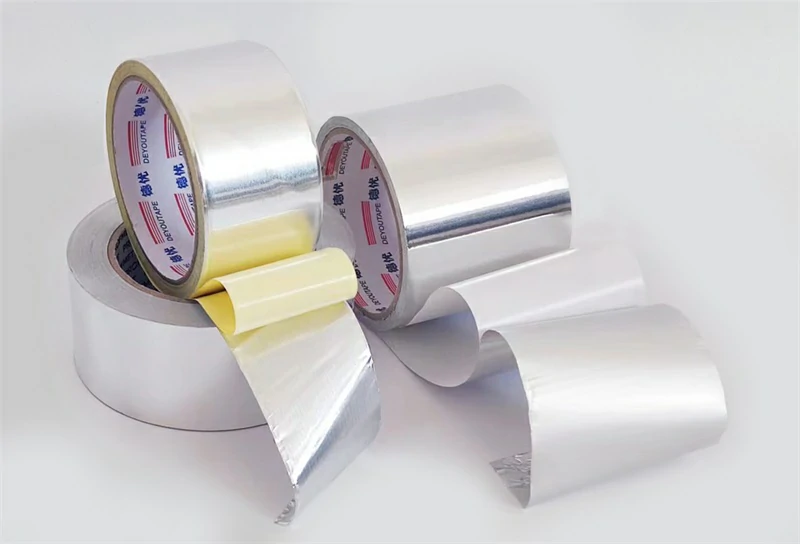

HVAC duct sealing tape, made from aluminum foil with a high-performance adhesive, is designed to withstand temperature fluctuations, air pressure, and moisture exposure that standard duct tape cannot handle.

Key Benefits

- HVAC Energy Efficiency: Sealing gaps prevents conditioned air from escaping, which reduces the workload on your system and lowers energy bills.

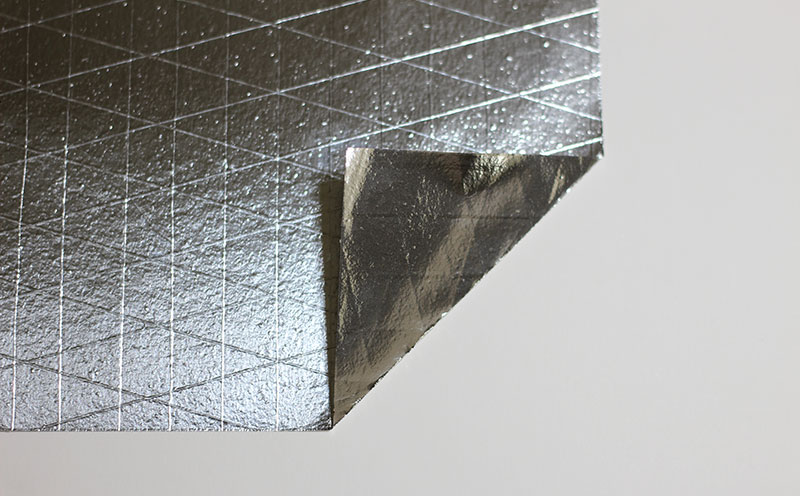

- Minimized Heat Loss/Gain: The reflective properties of aluminum HVAC tape help minimize thermal transfer through the duct walls.

- Improved Indoor Air Quality: Properly sealed ducts prevent dust, allergens, and other contaminants from being pulled into the system and circulated throughout your home.

- Quieter Operation: By reducing air turbulence and vibrations at leak points, foil tape for ductwork helps create a quieter HVAC system.

- Consistent Comfort: Sealed ducts ensure that air is distributed evenly, helping to maintain consistent temperatures in every room.

Note: For long-term performance, always use UL listed aluminum foil tape for HVAC applications.

Duct Seams and Joints

- Seals gaps between duct sections

- Reinforces loose or aging connections

Holes and Minor Damage

- Patches small punctures and tears

- Reinforces damaged ductboard before additional sealing

Registers and Grilles

- Secures duct-to-register connections

- Prevents conditioned air from escaping into wall cavities

Wall and Floor Penetrations

- Seals gaps where ductwork passes through walls or floors

- Reduces unwanted air infiltration

Step-by-Step Guide: How to Seal HVAC Ducts Properly

Step 1: Inspect the Ductwork

Identify visible leaks, loose joints, holes, or damaged insulation. Focus on seams, elbows, and transitions.

Step 2: Clean the Surface

Wipe the duct surface to remove dust, grease, or moisture. A clean surface ensures strong adhesion of the hvac duct sealing tape.

Step 3: Cut the Aluminum Foil Tape

Cut the tape long enough to extend at least 1–2 inches beyond the leak or seam on all sides.

Step 4: Apply the Tape

Peel off the liner and apply the tape smoothly over the leak. Press firmly along the center and edges to eliminate air bubbles.

Step 5: Seal All Critical Areas

Repeat the process for all joints, seams, and penetrations. Overlap tape slightly when sealing long seams.

Step 6: Final Inspection

Run your hand along the tape to ensure proper adhesion. Turn on the HVAC system and check for remaining air leaks.

Aluminum Foil Tape vs Duct Tape for Air Ducts

| Feature | Aluminum Foil Tape | Standard Duct Tape |

|---|---|---|

| Heat Resistance | Excellent | Poor |

| Long-Term Adhesion | High | Degrades quickly |

| Moisture Resistance | Strong | Weak |

| HVAC Code Compliance | UL listed options available | Not recommended |

Conclusion: Aluminum foil tape is the correct and professional solution for duct sealing.

Best Practices for Air Duct Sealing

- Use UL listed aluminum HVAC tape

- Apply tape to clean, dry surfaces only

- Avoid stretching the tape during application

- Combine with mastic for large gaps if required

- Inspect ducts annually for maintenance

Seal smarter with Deyou Tape.

Explore our professional HVAC duct sealing tape solutions or contact Deyou Tape today for expert support and product recommendations.