Aluminum foil tape not sticking is one of the most common frustrations in HVAC, insulation, and industrial sealing projects. You finish the job, only to find the tape curling at the edges or peeling off hours - or even minutes - later.

This isn’t just inconvenient. Foil tape adhesive failure can lead to air leaks, condensation issues, reduced energy efficiency, and costly rework. In most cases, the problem is not the tape itself, but how and where it’s used.

This practical guide explains why aluminum foil tape fails and shows exactly how to make aluminum foil tape stick better for reliable, long-term performance.

Why Aluminum Foil Tape Loses Adhesion

Before fixing the issue, it’s important to identify the root cause. Most adhesion problems fall into one (or more) of the categories below.

1. Surface Contamination (The #1 Cause)

Even surfaces that look clean may be coated with dust, oil, grease, moisture, or oxidation. Aluminum foil tape relies on direct molecular contact with the substrate. Any barrier—no matter how thin—can result in aluminum foil tape not sticking properly.

Common problem surfaces:

HVAC ducts, galvanized steel, insulation facings, dryer vents

2. Application at the Wrong Temperature

Adhesives have two limits:

- Application temperature (when the tape is installed)

- Service temperature (how hot or cold it can operate after bonding)

Applying standard foil tape in cold weather causes the adhesive to stiffen and lose tack, a leading cause of foil tape adhesive failure during winter installations. Extreme heat can also cause low-quality adhesives to soften and slide.

3. Moisture or Condensation on the Surface

Aluminum tape is often used in environments with temperature swings. If condensation, frost, or even invisible moisture is present during application, the tape bonds to the water layer - not the metal. Once the moisture evaporates or freezes, the bond fails.

4. Insufficient Application Pressure

Aluminum foil tape uses pressure-sensitive adhesive (PSA). Light hand pressure is often not enough. Without firm, even pressure, air pockets remain trapped beneath the foil, leading to lifting and edge failure over time.

5. Using the Wrong Adhesive Type

Not all aluminum foil tapes are the same:

- Acrylic adhesive foil tape

Best for high temperatures, HVAC systems, and long-term durability - Rubber-based foil tape

Better initial tack on rough or uneven surfaces

Using the wrong adhesive frequently results in delayed foil tape adhesive failure.

6. Low-Quality or Improperly Stored Tape

Thin foil backings, weak adhesive formulas, or tape stored in hot or humid conditions can all reduce performance—no matter how well it’s applied.

How to Make Aluminum Foil Tape Stick Better (Pro Checklist)

Follow these proven steps to achieve a permanent, professional-grade seal.

Step 1: Clean Until the Surface Is Truly Clean

Use a clean cloth with isopropyl alcohol or an approved solvent.

A good test: if the cloth picks up gray or dark residue, keep cleaning.

✔ Surface must be clean, dry, and oil-free before application.

Step 2: Match the Tape to the Environment

- Cold conditions: Use foil tape specifically rated for low-temperature application.

- High heat: Choose tape with a verified aluminum foil tape temperature rating (often 250–300°F for premium acrylic adhesives).

- For Textured Surfaces: Use a thicker foil with a higher adhesive coat weight to fill the gaps in the material.

Correct tape selection is essential to preventing aluminum foil tape not sticking issues.

Step 3: Apply Firm, Even Pressure

Professionals don’t rely on hands alone. Use a plastic squeegee or pressure roller to fully activate the adhesive and force it into the surface texture.

Step 4: Do Not Stretch the Tape

Aluminum foil does not have elastic memory. Stretching the tape during application causes it to pull back later, leading to edge lifting and failure.

Step 5: Allow Time for Full Bond Strength

Many foil tapes reach maximum adhesion after 24–72 hours. Avoid stressing the joint immediately after application.

When Replacement Is Better Than Repair

If the tape:

- Has dried or brittle adhesive

- Shows widespread lifting

- Was stored improperly

Replacing it is more reliable than trying to reapply or patch it.

Conclusion

When aluminum foil tape is not sticking, the cause is almost always surface preparation, temperature, pressure, or adhesive choice—not the concept of foil tape itself. By understanding the real reasons behind foil tape adhesive failure and applying proven installation techniques, you can confidently fix the issue and ensure long-lasting results.

Knowing how to make aluminum foil tape stick better saves time, improves performance, and protects the integrity of your system.

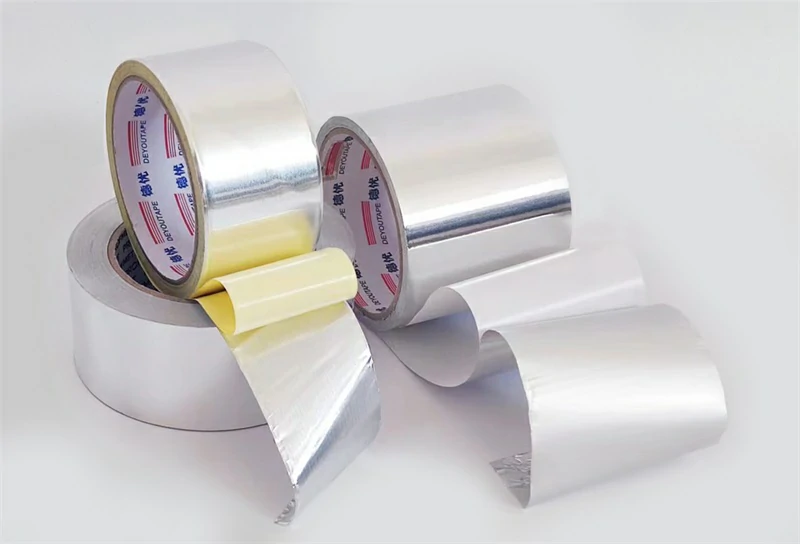

Get Reliable Aluminum Foil Tape from Deyou Tape

At Deyou Tape, we manufacture high-performance aluminum foil tapes engineered for HVAC, insulation, and industrial sealing—designed to bond reliably when applied correctly.

👉 Contact Deyou Tape today for expert guidance, technical