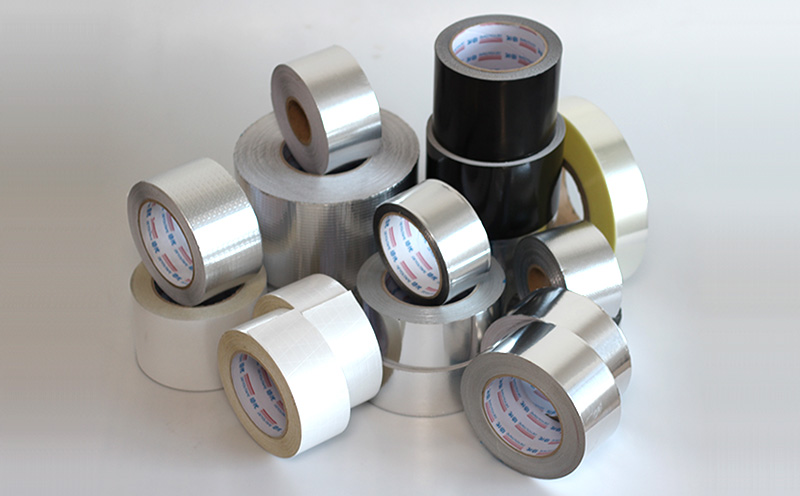

When specifying sealing materials for HVAC, insulation, or industrial applications, one comparison consistently matters: Acrylic vs Rubber Adhesive Aluminum Foil Tape. While both options use an aluminum foil backing to reflect heat and block moisture, the adhesive system beneath the foil determines performance, compliance, and long-term value.

This guide is written for commercial investigation search intent, helping buyers, contractors, and procurement teams evaluate aluminum foil tape options and drive informed purchase decisions.

Understanding Aluminum Foil Tape Adhesives

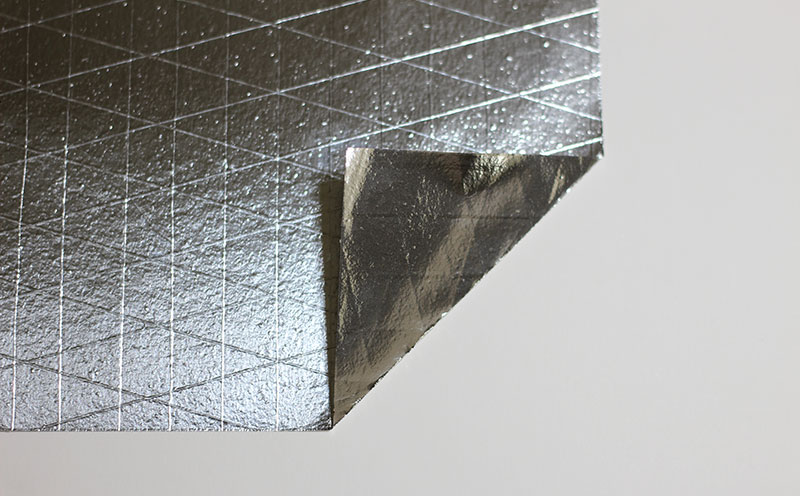

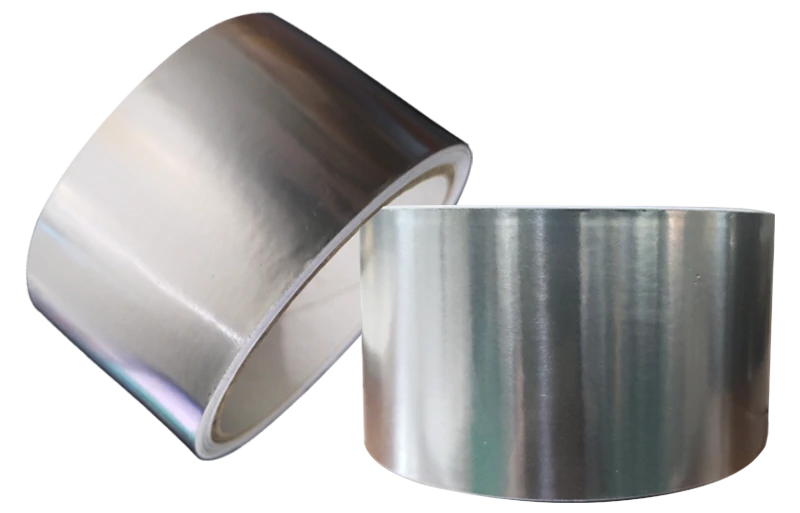

Aluminum foil tape combines a pure aluminum foil backing with either an acrylic adhesive or a rubber-based adhesive. Both are designed for sealing, joining, and insulating—but their behavior differs significantly depending on temperature, exposure, and service life expectations.

Choosing between acrylic vs rubber adhesive foil tape directly affects:

- Durability and aging performance

- Resistance to heat, UV, and moisture

- Maintenance frequency and total cost of ownership

Acrylic Adhesive Aluminum Foil Tape

Acrylic adhesive aluminum foil tape uses a solvent-based or water-based acrylic adhesive that cures over time, forming a strong and permanent bond. In most professional scenarios, acrylic adhesive foil tape vs rubber is the preferred long-term solution.

Key Advantages

- Wide temperature resistance: Typically from -40°F to 250°F, with specialty grades reaching higher

- Excellent UV and weather resistance: No cracking, drying, or yellowing

- Long-term adhesion: Bond strength increases over 24–72 hours

- High resistance to moisture, chemicals, and solvents

- Extended service life in HVAC and outdoor environments

-

Limitations

- Lower initial tack than rubber adhesive

- Requires clean surfaces and firm application pressure

- Higher upfront cost compared to rubber-based tape

Best Applications

- HVAC duct sealing and insulation systems

- Vapor barriers and insulation facing

- Outdoor installations and exposed environments

- Projects requiring fire, smoke, or building-code compliance

-

For buyers focused on reliability and compliance, acrylic vs rubber adhesive aluminum foil tape typically favors acrylic.

Rubber Adhesive Aluminum Foil Tape

Rubber adhesive foil tape uses synthetic or natural rubber combined with tackifiers to provide instant, aggressive adhesion.

Key Advantages

- Very high initial tack for immediate bonding

- Adheres well to rough, dusty, or low-energy surfaces

- Performs reliably in low-temperature installations

- Lower initial purchase cost

Limitations

- Limited temperature resistance (usually below 90–120°C)

- Poor UV and aging resistance

- Adhesive may harden, ooze, or fail over time

- Not recommended for long-term or outdoor exposure

Best Applications

- Temporary sealing and repairs

- Indoor environments with stable temperatures

- Short-term projects requiring fast installation

In direct comparisons of acrylic vs rubber adhesive foil tape, rubber performs well short term but degrades faster.

Acrylic vs Rubber Adhesive Aluminum Foil Tape: Comparison Table

| Performance Factor | Acrylic Adhesive | Rubber Adhesive |

|---|---|---|

| Initial Tack | Moderate | Very High |

| Long-Term Adhesion | Excellent | Limited |

| Temperature Resistance | High | Low–Moderate |

| UV & Aging Resistance | Excellent | Poor |

| Moisture Resistance | Excellent | Moderate |

| Typical Use | HVAC, insulation, outdoor | Temporary, indoor |

This side-by-side view highlights why adhesive selection is critical in aluminum foil tape procurement.

How to Choose the Right Aluminum Foil Tape

To make an informed commercial purchase, evaluate:

- Service temperature: High-heat systems favor acrylic adhesives

- Expected lifespan: Permanent installations require acrylic performance

- Surface condition: Rough surfaces may benefit from rubber’s high tack

- Environmental exposure: UV, moisture, and chemicals demand acrylic durability

- Compliance requirements: Many HVAC standards specify acrylic adhesive foil tape

For most professional projects, acrylic adhesive foil tape vs rubber is not simply a price comparison—it is a risk and performance decision.

Commercial Buying Insight

Although rubber adhesive foil tape often has a lower upfront cost, acrylic adhesive aluminum foil tape frequently delivers a lower total cost of ownership. Fewer failures, reduced maintenance, and longer service life translate into better value for commercial and industrial buyers.

Conclusion

The decision between Acrylic vs Rubber Adhesive Aluminum Foil Tape depends on environment, performance expectations, and project duration. Rubber adhesive tapes are effective for short-term, indoor applications, while acrylic adhesive foil tapes are the industry standard for HVAC, insulation, and long-term sealing.

Understanding the differences between acrylic vs rubber adhesive foil tape ensures you select the right aluminum foil tape the first time - saving cost, time, and risk.

Ready to choose the right aluminum foil tape for your application?

Deyou Tape supplies high-performance acrylic adhesive aluminum foil tape and rubber adhesive foil tape engineered for commercial, HVAC, and industrial use.

Contact Deyou Tape today for technical guidance, product samples, or a tailored quotation to support your purchasing decision.