Improving energy efficiency in buildings depends not only on insulation and HVAC equipment, but also on how well systems are sealed. One critical yet often underestimated material is aluminum sealing tape. When used correctly, aluminum sealing tape significantly reduces energy loss by sealing air leaks, supporting insulation, and maintaining long-term system performance.

This article explains how aluminum sealing tape contributes to better energy efficiency in residential, commercial, and industrial buildings.

What Is Aluminum Sealing Tape?

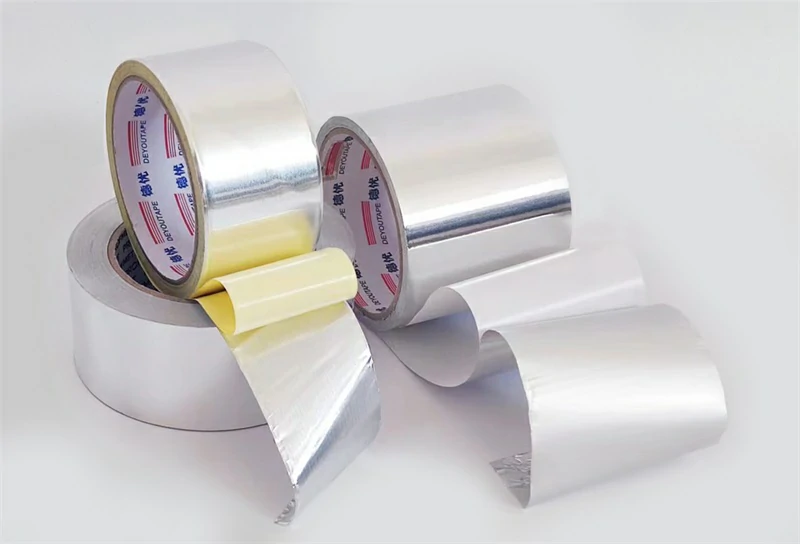

Aluminum sealing tape is a high-performance, pressure-sensitive adhesive tape constructed with a "dead soft" aluminum foil backing. It is designed to seal joints, seams, and connections in HVAC systems, insulation materials, and building envelopes where airtightness and thermal stability are essential.

Unlike general-purpose tapes, aluminum sealing tape resists heat, moisture, and aging, allowing it to maintain adhesion and sealing performance over time. For this reason, it is widely used in HVAC ductwork, insulation systems, and energy-efficiency upgrades.

Reducing Air Leakage with Aluminum Sealing Tape

Air leakage is one of the primary causes of energy inefficiency in buildings.

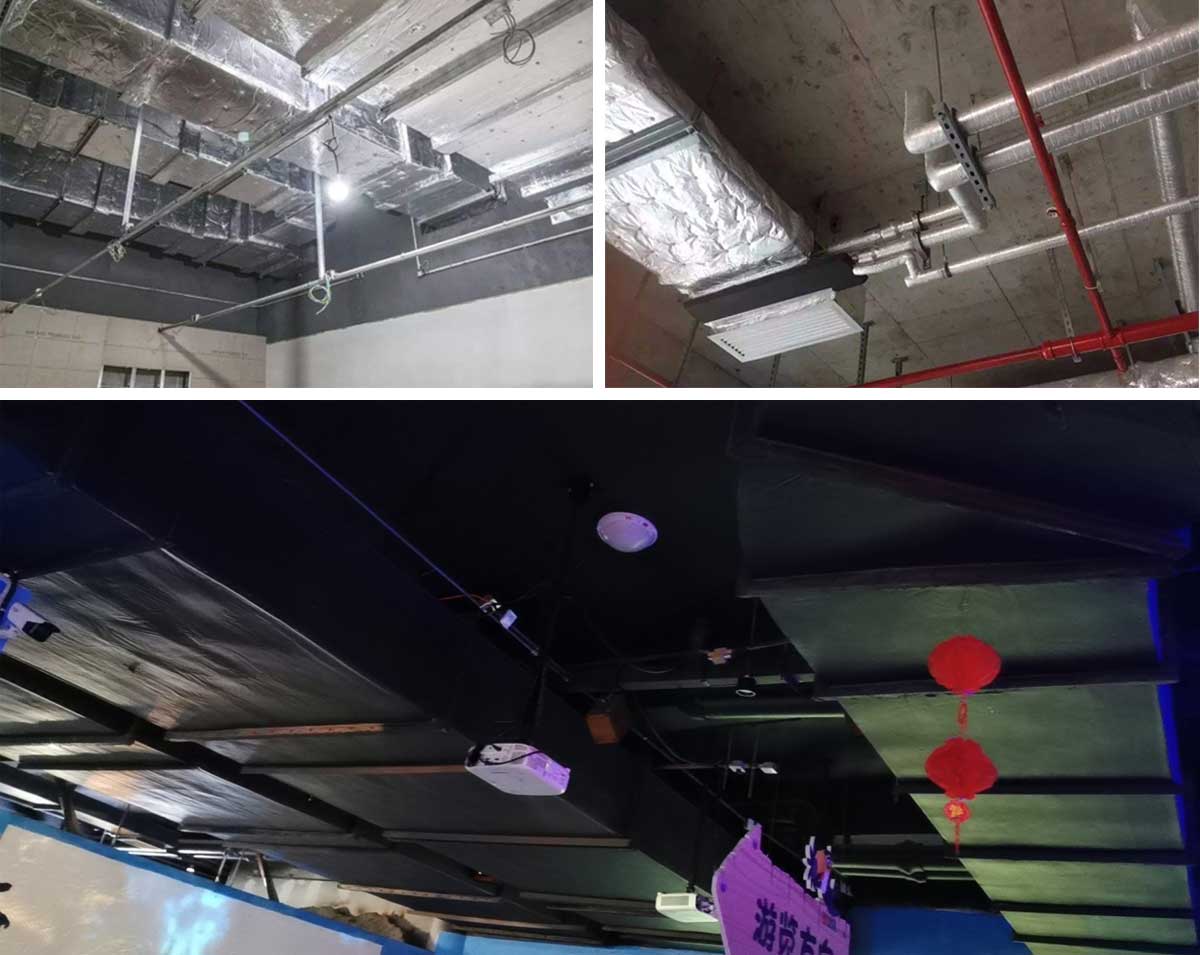

Airtight Sealing of HVAC Ducts

When applied to duct joints and seams, aluminum sealing tape creates a durable, airtight bond that prevents conditioned air from escaping into unconditioned spaces. This helps ensure that heated or cooled air reaches its intended destination.

Energy Efficiency Impact

- Reduced air loss improves HVAC system efficiency

- Less energy is required to maintain indoor temperatures

- Overall heating and cooling costs are lowered

Proper duct sealing with aluminum sealing tape is especially important in large commercial buildings, where even small leaks can result in significant energy waste.

Supporting Insulation Performance

Insulation systems rely on continuity to function effectively.

Aluminum Sealing Tape for Insulation Systems

When used on insulation seams, vapor barriers, and reflective facings, aluminum sealing tape helps maintain an unbroken thermal layer. This prevents gaps that allow heat transfer and reduces the risk of moisture intrusion.

Improved Thermal Control

By sealing exposed edges and joints, aluminum sealing tape minimizes thermal bridging, helping insulation perform as designed.

Heat Reflection and Temperature Stability

The aluminum foil backing of aluminum sealing tape provides reflective properties that enhance thermal performance.

- Reflects radiant heat away from conditioned spaces in warm environments

- Helps retain heat within ducts and insulated systems in cold climates

- Stabilizes temperatures and reduces HVAC cycling

These properties contribute directly to improved energy efficiency and occupant comfort.

Long-Term Performance and Durability

Energy efficiency gains are only meaningful if they last over time.

Resistance to Heat and Aging

Aluminum sealing tape maintains adhesion and structural integrity under temperature extremes, vibration, and airflow. Unlike conventional tapes, it does not dry out or peel prematurely.

Consistent Energy Performance

Because the seal remains intact, buildings continue to benefit from reduced air leakage and improved insulation performance throughout the system’s lifespan.

Code Compliance and Energy Standards

Many building and energy-efficiency standards require effective duct sealing and insulation continuity.

- Aluminum sealing tape is commonly used in code-compliant HVAC installations

- UL-rated aluminum sealing tape supports fire safety and performance requirements

- Proper sealing improves results in energy audits and efficiency certifications

Using the correct sealing materials helps ensure regulatory compliance while improving energy outcomes.

Lower HVAC Load and Operating Costs

By reducing air leakage and improving insulation efficiency, aluminum sealing tape helps HVAC systems operate more efficiently.

Key benefits include:

- Lower heating and cooling demand

- Reduced equipment run time

- Less mechanical wear and maintenance

- Long-term reduction in energy and operating costs

These advantages make aluminum sealing tape a cost-effective solution for both new construction and retrofit projects.

Common Applications in Energy-Efficient Buildings

Aluminum sealing tape is widely used in energy-focused building applications, including:

- HVAC duct sealing and repair

- Insulated duct wrap systems

- Radiant barrier installations

- Mechanical room insulation

- Energy-efficiency retrofits and upgrades

Its versatility makes it suitable for residential, commercial, and industrial environments.

Conclusion

Aluminum sealing tape plays a critical role in improving building energy efficiency by sealing air leaks, supporting insulation systems, reflecting heat, and maintaining long-term durability. Although small in size, its impact on HVAC efficiency, energy consumption, and operating costs is substantial.

For buildings seeking reliable, long-lasting energy performance, aluminum sealing tape is an essential component of a well-sealed and energy-efficient system.

Looking for high-performance aluminum sealing tape that delivers long-term energy efficiency and reliable HVAC sealing?

Deyou Tape offers professionally engineered aluminum sealing tape solutions designed for airtight duct sealing, insulation support, and durable performance in demanding building environments.

👉 Contact Deyou Tape today to learn more about our aluminum sealing tape products and find the right solution for your energy-efficient building projects.