Choosing the right aluminum foil tape is crucial for ensuring long-term performance, safety, and efficiency—especially in professional HVAC, insulation, and duct applications. With a range of options on the market, understanding how to choose aluminum foil tape helps buyers avoid product failure, rework, and unnecessary costs.

This comprehensive guide will help you evaluate key features, application requirements, and performance standards to confidently select the best aluminum foil tape for your needs.

Why Choosing the Right Aluminum Foil Tape Matters

Aluminum foil tape is essential in sealing, insulating, and protecting ducts, HVAC systems, and insulation materials. However, not all tapes are designed for the same conditions. Variations in adhesive type, foil thickness, heat resistance, and compliance standards can significantly impact performance.

Making the correct selection ensures:

- Reliable sealing and adhesion

- Improved energy efficiency

- Long-term durability under heat and moisture

- Compliance with industry and safety standards

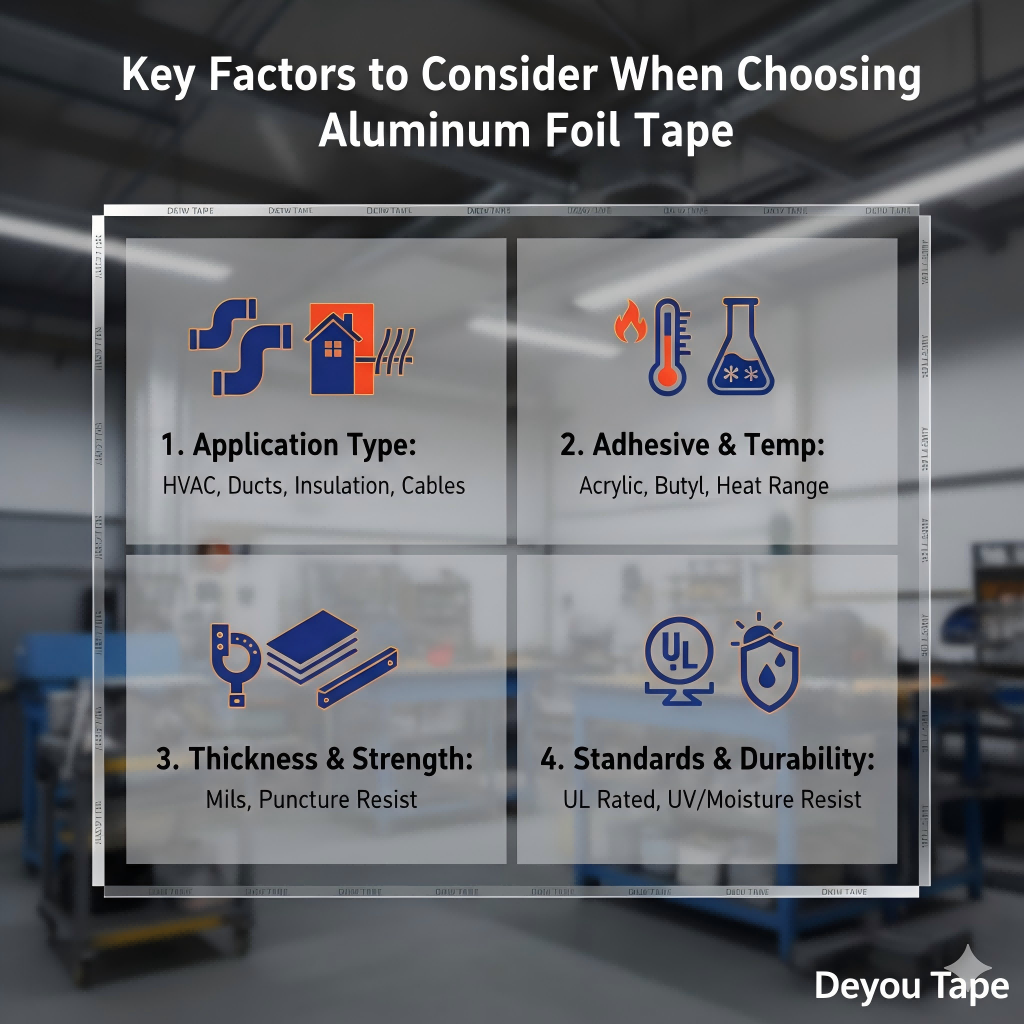

Key Factors to Consider When Choosing Aluminum Foil Tape

1. Defining Your Application

Start by defining where and how the aluminum foil tape will be used:

- Aluminum foil tape for HVAC systems must withstand temperature fluctuations, vibration, and airflow pressure, and require high tack and moisture resistance.

- For insulation, the tape should provide a strong vapor barrier, often flame-retardant (UL 723 rated), and be able to conform easily to insulation surfaces.

- In ductwork, durability is paramount, especially in high-pressure environments, to ensure airtight seals and performance under continuous operation.

2. Adhesive Type

The type of adhesive directly impacts the tape’s performance and longevity. To choose aluminum foil tape correctly, match the adhesive to your environmental conditions:

- Acrylic adhesives are ideal for HVAC aluminum duct tape due to their excellent temperature resistance and long-term durability. They are also resistant to UV light and chemicals, making them suitable for outdoor use and high-heat environments.

- Butyl adhesives provide superior initial tack and are ideal for irregular or challenging surfaces, with fast application speeds. However, they are not as resilient under long-term temperature fluctuations.

For commercial and industrial use, solvent-based acrylic adhesives are often the preferred choice because of their reliability and resistance to aging.

3. Foil Thickness and Strength

Thicker aluminum foil offers greater durability and performance. When evaluating how to choose aluminum foil tape, consider foil thickness in relation to mechanical stress and environmental exposure:

- 1.5 to 2.0 mils: Best for wrapping and masking irregular shapes due to high conformability.

- 3.0 to 5.0 mils: Ideal for aluminum foil tape for HVAC systems, providing puncture resistance needed for metal ductwork under high pressure.

Thicker foil provides better durability and enhanced moisture barrier performance, ensuring long-lasting seals.

4. Temperature and Heat Resistance

High-quality aluminum foil tape must perform reliably across a wide temperature range. HVAC and heating systems require tapes that can maintain adhesion under continuous heat exposure.

- Poor-quality tapes may crack, peel, or dry out over time due to heat exposure. Always verify the temperature range and suitability for your specific needs.

5. Compliance and Standards

For professional applications, compliance is essential. Look for aluminum foil tape that meets recognized standards such as:

- UL 181 for HVAC duct sealing

- Fire resistance and flame retardancy requirements

Certified products are a safer choice when selecting the best aluminum foil tape for commercial and industrial projects.

Matching Aluminum Foil Tape to Common Use Cases

Aluminum Foil Tape for HVAC

- Sealing air ducts and joints

- Improving airflow efficiency

- Preventing air leakage and condensation

Aluminum Foil Tape for Insulation

- Joining insulation panels

- Creating a vapor and moisture barrier

- Enhancing thermal performance

Aluminum Foil Tape for Ducts

- Sealing seams, elbows, and transitions

- Supporting long-term airtight performance

- Withstanding vibration and temperature changes

Choosing a tape designed specifically for each application ensures optimal results.

How to Identify the Best Aluminum Foil Tape for Your Project

When comparing products, ask the following:

- Is the adhesive suitable for my temperature range?

- Is the foil thickness and durability sufficient for my application?

- Does the tape meet the necessary HVAC or insulation standards?

- Is it designed for professional or industrial use?

Answering these questions will help narrow down the best option and reduce the risk of failure.

Conclusion

Understanding how to choose aluminum foil tape is essential for achieving reliable sealing, insulation, and long-term performance. By evaluating application requirements, adhesive types, foil thickness, and compliance standards, buyers can confidently select the best aluminum foil tape for HVAC, insulation, and ductwork applications.

Making the right choice upfront not only improves system efficiency but also reduces maintenance costs and extends service life.

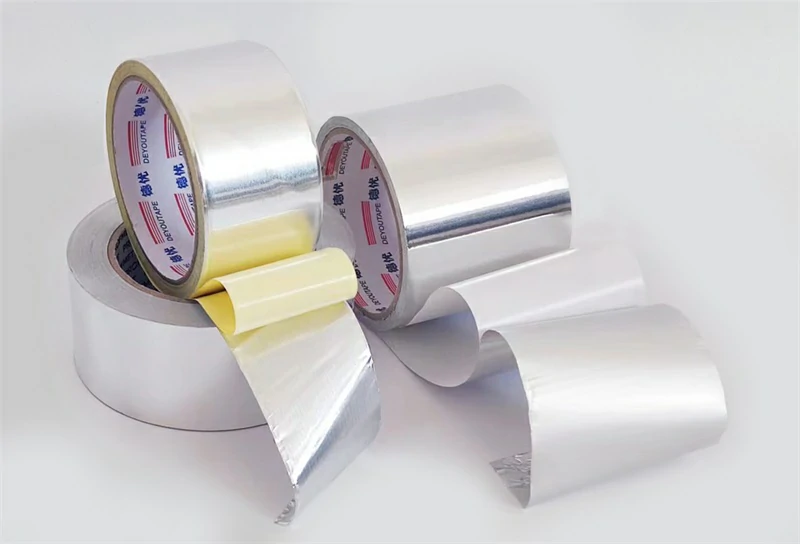

Looking for high-quality aluminum foil tape?

At Deyou Tape, we offer a range of aluminum foil tapes designed for HVAC, insulation, and duct applications. Our tapes are engineered for optimal performance in professional and commercial environments.

Contact Deyou Tape today to find the best aluminum foil tape for your project and ensure long-lasting, reliable results.