HVAC duct tape is a special type of tape used in heating, ventilation, and air conditioning (HVAC) systems. Unlike regular adhesive tapes, HVAC duct tape is made to withstand extreme temperatures, moisture, and pressure, making it suitable for the conditions inside ducts.

The primary purpose of HVAC duct tape is to prevent air leaks. Leaks in ductwork can lead to significant energy loss, reduced system efficiency, and comfort issues. By properly sealing joints, seams, and punctures in ducts, HVAC duct tape helps to maintain the integrity of the HVAC system.

Types of HVAC Duct Tape:

Choosing the right HVAC duct tape depends on the material of the ductwork, the environmental conditions (such as moisture or temperature), and the specific application you're working with.

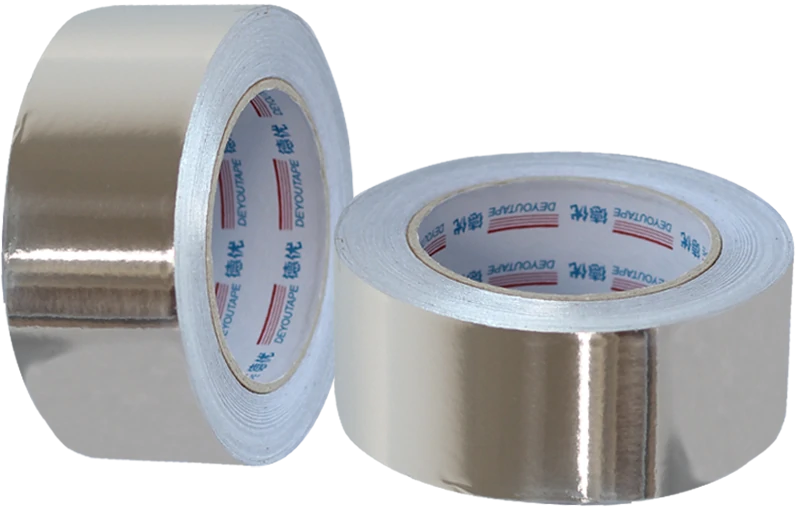

1. Aluminum Foil Tape

Features: Made with an aluminum backing and a strong adhesive.

Characteristics:

Excellent heat reflectivity: This makes it ideal for applications where temperature control is important.

Good moisture resistance: The foil provides a barrier against moisture.

Can be used on rigid surfaces: It conforms well to smooth, rigid ductwork.

Use: This is the most common type of HVAC tape and is used for sealing joints and seams in metal and flexible ducts. It's resistant to high temperatures, moisture, and UV light.

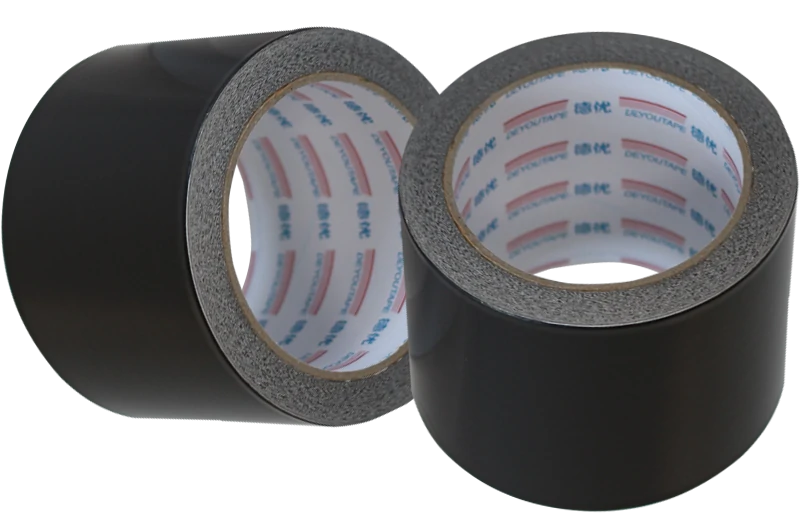

2. Cloth-Backed Tape

Features: This tape has a cloth backing with a strong adhesive on one side.

Characteristics:

High tensile strength: The cloth backing provides durability and resistance to tearing.

Flexibility: It can conform to various shapes, including curved or irregular surfaces.

Versatility: It can be used for a wider range of applications beyond just sealing ducts.

Use: Cloth-backed tape is more flexible than aluminum foil tape and is often used for sealing flexible ducts or areas where flexibility is important.

3. Specialty tapes

This category includes tapes designed for specific applications or environments, such as high-temperature or UV-resistant tapes.

How to Choose the Correct Tape for HVAC Systems

Choosing the right tape for your HVAC system is crucial for ensuring a proper seal, preventing energy loss, and maintaining system efficiency. Here's a breakdown of the key factors to consider:

1. Duct Material:

Metal Ducts:

Aluminum foil tape is often a good choice for sealing rigid metal ducts. Its heat reflectivity and moisture resistance are advantageous.

Flexible Ducts:

Cloth-backed tapes are often preferred for flexible ducts due to their strength and flexibility.

Insulated Ducts:

Use tape specifically designed for sealing seams in insulation. Foil-faced tapes are often used for foil-faced insulation.

2. Application Location and Conditions:

Temperature:

If the ducts are in a high-temperature environment (e.g., an attic), choose a tape with high-temperature resistance.

Humidity:

In humid environments, select a tape with good moisture resistance to prevent adhesive breakdown. Cloth-backed tapes can also offer some moisture resistance, but aluminum foil tape is typically the most effective in these situations.

Outdoor Exposure:

For outdoor ductwork, choose a tape that is UV-resistant and weather-resistant to withstand sunlight and the elements.

3. Tape Properties:

Adhesion Strength:

Ensure the tape has strong initial tack and good ultimate adhesion to the duct material.

Durability:

Choose a tape that is resistant to tearing, abrasion, and punctures. For high-pressure ducts or systems with a lot of airflow, aluminum foil tapes provide a high level of durability.

Flexibility:

If sealing irregular surfaces or flexible ducts, choose a tape with good flexibility.

4. Color and Appearance

Aesthetic Considerations: While not as important as functionality, some HVAC tapes come in different colors (e.g., silver, black, or white) for aesthetic purposes. Aluminum foil tapes have a metallic finish that can help reflect heat and is commonly used for both performance and appearance. If appearance is important, choose a tape that blends in with the ductwork or is designed to be discreet.

5. Ease of Application

User-Friendly: Look for tapes that are easy to apply, especially if you’re doing the work yourself. Tapes that have a peel-and-stick backing or are easy to tear by hand (like cloth-backed HVAC tape) can save time and reduce frustration during installation or repairs.

6. Building Codes and Standards:

Check local building codes and regulations for specific requirements regarding duct sealing and tape usage.

Look for tapes that meet relevant industry standards and certifications.

Using the right HVAC duct tape ensures that your system operates efficiently, with no air leaks, heat loss, or contamination in the air being circulated. It helps to maintain the system’s energy efficiency, reduce wear on equipment, and ensure indoor air quality is not compromised.

In short, HVAC duct tape is a critical tool in maintaining a well-functioning HVAC system, offering reliable sealing, durability, and safety across a variety of installations and repairs.

Deyou Tape high-quality aluminum foil tape products are certified by the Quality Management System and tested for fire resistance, waterproofing, and chemical & UV resistance. We serve customers across 12 countries. Contact us today for customized solutions tailored to your aluminum foil tape needs.