In the world of heating, ventilation, and air conditioning, efficiency depends on airtight connections and high-performance materials. One small but critical component in these systems is HVAC aluminum foil tape. Its unique properties make it particularly useful for maintaining the integrity and efficiency of these systems. While often overlooked, this specialized HVAC sealing tape plays a key role in sealing, insulating, and protecting air duct systems.

Understanding what is HVAC aluminum foil tape and its various benefits helps contractors and engineers make better installation and maintenance decisions for long-term system performance.

What Is HVAC Aluminum Foil Tape?

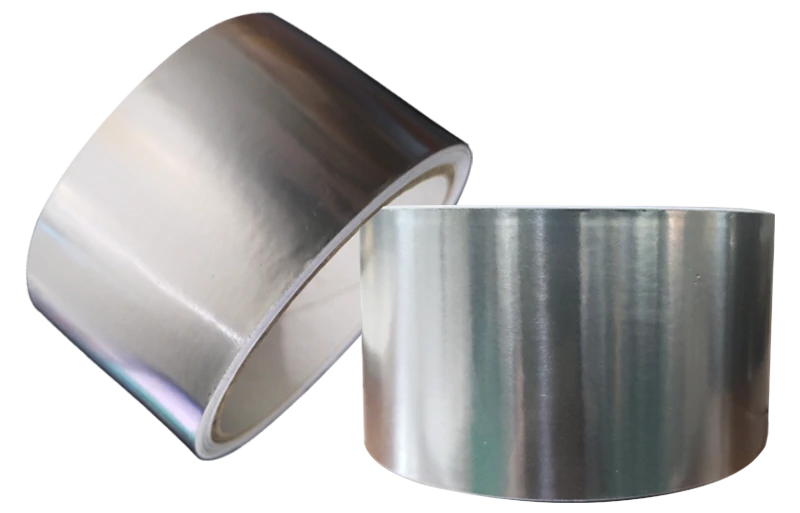

HVAC aluminum foil tape is a pressure-sensitive adhesive tape featuring an aluminum foil backing. It is engineered for HVAC environments where heat resistance, moisture protection, and airtight sealing are required.

Unlike conventional duct tape, aluminum foil HVAC tape resists temperature extremes, humidity, and aging without losing adhesion. It is commonly used on air ducts, insulation systems, and HVAC equipment housings. In professional installations, foil tape HVAC applications often require compliance with industry standards such as UL 181 aluminum foil tape certification.

Why Use Aluminum Foil Tape in HVAC Systems?

Understanding why use aluminum foil tape in HVAC systems comes down to efficiency, safety, and durability.

Airtight Sealing and Energy Efficiency

Air leakage significantly reduces HVAC efficiency. Aluminum tape for air ducts provides a strong, long-lasting seal at joints and seams, minimizing air loss, preventing heat transfer, and improving overall system performance.

Heat and Temperature Resistance

A frequent question is: is aluminum foil tape heat resistant? The answer is yes. HVAC aluminum tape is designed to withstand both high and low temperatures, making it suitable for heating ducts, cooling lines, and exhaust systems. Its proven HVAC foil tape temperature resistance ensures stable performance over time.

Moisture and Vapor Barrier Protection

The aluminum backing acts as an effective vapor barrier. When used as aluminum foil tape insulation support, it helps protect duct insulation from moisture intrusion and condensation-related damage.

Sound Dampening

The tape's adhesive properties and ability to adhere to various surfaces make it useful for sound dampening in HVAC systems. It can be applied to seal gaps and joints, reducing noise transmission and improving acoustic performance.

Indoor Air Quality and Code Compliance

Airtight sealing prevents dust, allergens, and pollutants from entering the HVAC system. Additionally, many building codes require UL 181 aluminum foil tape for duct sealing to meet fire safety and performance standards.

HVAC Aluminum Foil Tape vs Duct Tape

Comparing HVAC aluminum foil tape vs duct tape highlights why foil tape is the professional choice.

- Standard duct tape degrades under heat and airflow

- HVAC aluminum tape maintains adhesion long term

- Foil tape HVAC products meet code and safety requirements

For reliable and code-compliant installations, HVAC sealing tape made from aluminum foil is the correct solution.

Key Benefits of HVAC Aluminum Foil Tape

- Durable HVAC Sealing Tape: HVAC aluminum tape maintains strong adhesion even under vibration, airflow, and temperature cycling.

- Aluminum Foil Tape Insulation Support: Used over insulation seams, aluminum foil tape improves thermal efficiency and protects insulation materials.

- Fire and Safety Performance: Many HVAC foil tapes are flame-resistant and tested for safety compliance.

- Clean and Professional Appearance: The metallic finish provides a neat, professional look commonly required in commercial and industrial HVAC systems.

Common Applications of Aluminum Tape for HVAC

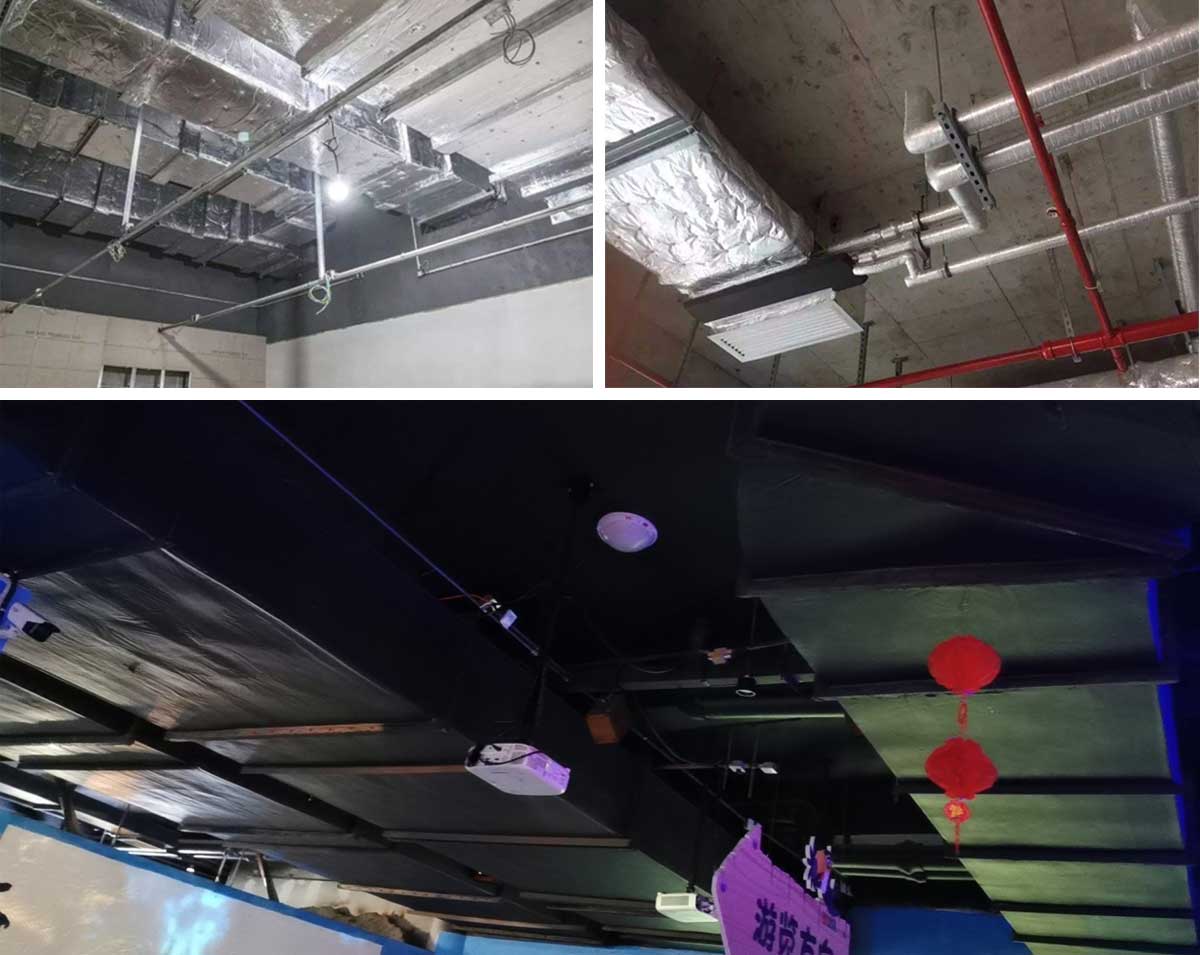

Aluminum foil tape for air duct sealing is widely used in:

- HVAC duct seams and joints

- Insulated duct wrap systems

- Air handlers and HVAC equipment housings

- Dryer and exhaust vent connections

- Commercial and industrial HVAC installations

- Due to its reliability, HVAC aluminum tape is used in both new installations and retrofit projects.

Standards and Compliance: UL 181 Aluminum Foil Tape

In many regions, HVAC installations require UL 181 aluminum foil tape. This certification verifies adhesion strength, temperature resistance, flame spread, and mold resistance.

Using UL-rated HVAC foil tape ensures:

Code compliance

Long-term system performance

Reduced inspection and liability risks

For professional and commercial projects, UL 181 compliance is often mandatory.

Conclusion: Why HVAC Aluminum Foil Tape Matters

HVAC aluminum foil tape is a critical component of efficient, durable, and code-compliant HVAC systems. From airtight sealing and heat resistance to moisture protection and safety compliance, aluminum foil HVAC tape delivers performance that general-purpose tapes cannot match.

Understanding what HVAC aluminum foil tape is and why it is important helps contractors, engineers, and facility managers make informed decisions that improve system reliability and long-term value.

Looking for reliable, high-performance HVAC aluminum foil tape for professional duct sealing and insulation?

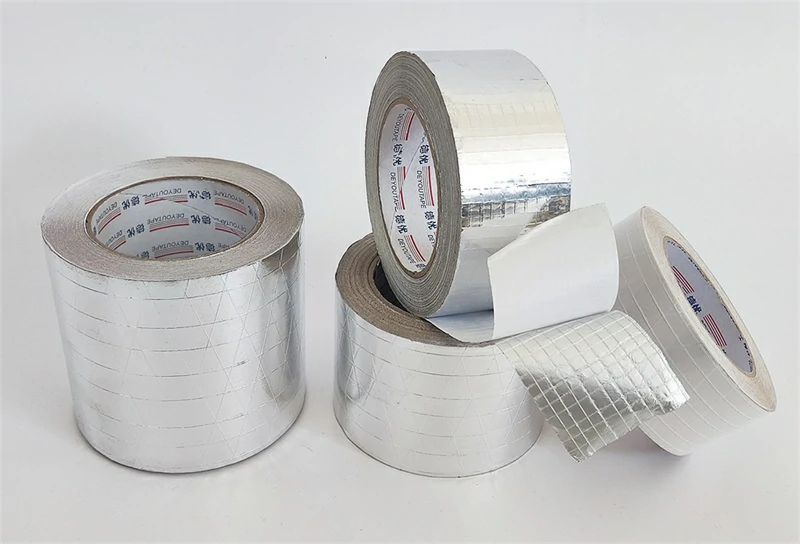

Deyou Tape offers durable HVAC sealing tape solutions designed for energy efficiency, temperature resistance, and industry compliance.

👉 Contact Deyou Tape today to find the right aluminum foil tape for your HVAC applications.