When it comes to HVAC (Heating, Ventilation, and Air Conditioning) systems, the right hvac tape adhesive is crucial for ensuring proper sealing and insulation. Various adhesive types are specifically designed to meet the requirements of different HVAC applications and environments. Understanding their unique characteristics can help you choose the best hvac tape for your needs.

What Is HVAC Tape Adhesive?

HVAC tape adhesive is the bonding material that allows HVAC tape to stick securely to surfaces like metal ducts, insulation, and plastic components. Depending on the type, these adhesives provide strength, flexibility, heat resistance, and weather protection - qualities essential for reliable HVAC performance.

Features and Benefits of HVAC Tape Adhesive

Strong Bonding Power – Ensures long-lasting seals on ducts and insulation.

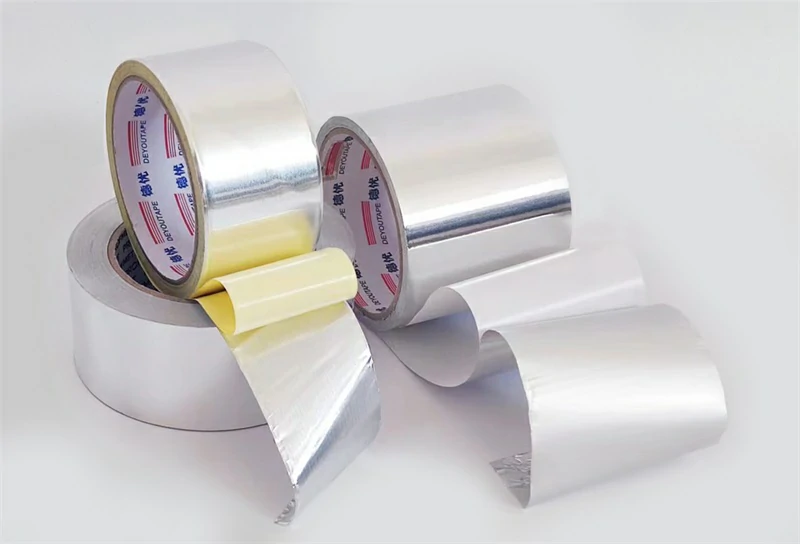

Versatility – Compatible with aluminum foil tape, hvac tape, and other materials.

Temperature Resistance – Maintains adhesion in both hot and cold environments.

Moisture Protection – Prevents leaks and corrosion in HVAC systems.

Ease of Application – Options like PSA allow fast and hassle-free use.

Common Adhesive Types for HVAC Tape

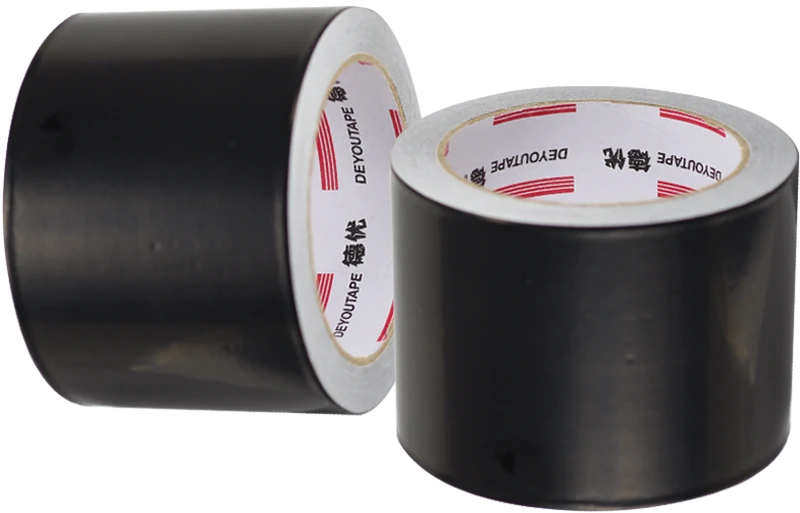

Rubber Adhesive: A popular choice for hvac tape due to its flexibility and strong initial tack. This type of adhesive provides a reliable bond to many materials found in HVAC systems and offers good adhesion even in cold temperatures.

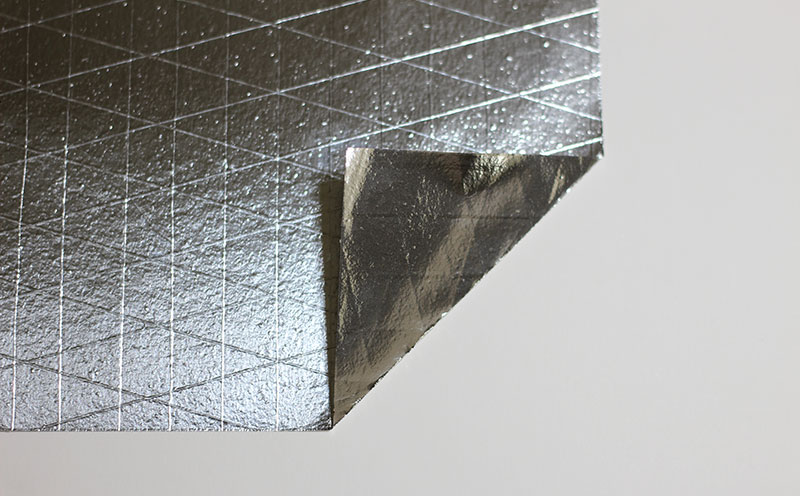

Acrylic Adhesive: This is a versatile and widely used adhesive type in hvac tape. It provides good adhesion to a variety of surfaces, including metal, plastic, and insulation materials. Acrylic adhesive is also known for its durability, temperature resistance, and UV resistance, making it suitable for both indoor and outdoor applications.

Butyl Adhesive: A synthetic rubber adhesive known for its excellent weather and water-resistant properties. It is commonly used in HVAC tapes to seal joints and seams, preventing air leaks and moisture infiltration.

Pressure-Sensitive Adhesive (PSA): Designed to create a strong bond when pressure is applied to the tape. PSA adhesives are easy to apply and provide instant adhesion to a variety of surfaces, making them ideal for quick and efficient installation.

Silicone Adhesive: This adhesive is known for its high-temperature resistance and excellent weatherability. It maintains its properties over a wide temperature range, making it suitable for HVAC applications exposed to extreme heat or cold. Silicone adhesive also resists UV radiation and aging, ensuring long-lasting performance in outdoor installations.

Choosing the right HVAC tape adhesive ensures reliable performance, whether you’re working on duct sealing, insulation, or system repairs. By matching the adhesive to your project needs, you’ll achieve strong, durable, and efficient results for any hvac tapes application. For example, a heavy-duty aluminum foil tape might use an acrylic or silicone adhesive for high-temperature ducts, while a more flexible solution might rely on a rubber or butyl adhesive for sealing seams in a tight space. Knowing the benefits of each adhesive type ensures you select the perfect hvac tape to get the job done right.

Key differences between acrylic and rubber-resin adhesives: